Just – Evotec Biologics seamlessly integrates services to deliver flexible first-in-human (FIH) programs, supporting our partners from candidate selection to successful Investigative New Drug (IND) submission. We have a proven track record with a range of biotherapeutics including monoclonal antibodies and innovative antibody formats such as bispecifics and Fc-fusion proteins. Our expert scientists and regulatory team are dedicated to guiding our partners to regulatory success.

Selecting the Right CDMO for Your FIH Program

Successfully advancing your candidate from gene to IND can be challenging, especially for emerging biotechnology companies. To navigate this journey, it’s crucial to partner with a technology-driven CDMO that offers:

- Extensive experience in progressing FIH projects from candidate selection to IND submission

- Expertise in navigating the complexities of an IND program with maximum speed and minimal risk

- Localized manufacturing in the US and EU, with integrated process development and manufacturing facilities

First-In-Human Timeline

Illustrative First-In-Human Timeline

First-In-Human Manufacturing Scope

During a first-in-human manufacturing program we can offer the following services:

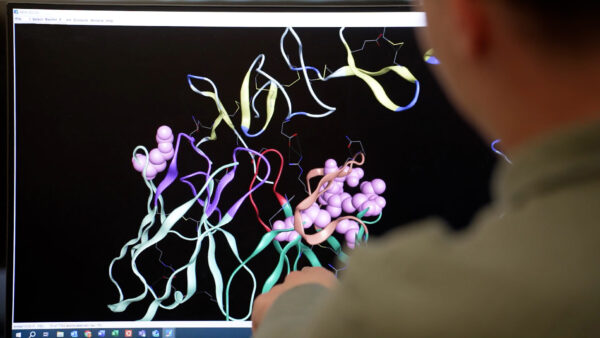

- Lead sequence validation & optimization towards increased "manufacturability"

- Cell line development

- Process development

- Analytical development

- Formulation development

- Master cell banking

- Non-cGMP drug substance manufacturing

- Stability studies for drug substance & drug product

- Regulatory support

Read Our Customer Case Study

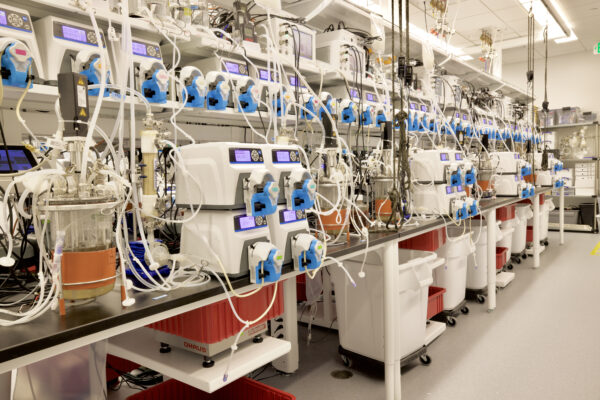

Why Choose a Continuous Platform for First-In-Human Manufacturing?

Selecting a continuous manufacturing platform for Phase 1 production sets you up for success from the start of your clinical program, giving you the highest productivity, best quality, lowest risk and greatest flexibility as you proceed towards commercialization.

Adopting a continuous biomanufacturing platform for early phase clinical manufacturing is the most streamlined strategy to leverage the benefits of intensified bioprocessing and allows you to build success into your process from the start.

- Higher productivity: Adopt a manufacturing strategy delivering high productivity thereby reducing the need for clinical re-supply runs and minimizing your future Cost of Goods.

- Higher quality: Gain greater control of your biopharmaceutical's quality attributes with a manufacturing approach encouraged by regulators.

- Reduced risk: De-risk your journey from IND to BLA by avoiding large changes in production scale, technology and sites.

- Greater flexibility: Our intensified continuous manufacturing platform combined with our agile cGMP J.POD facility design delivers the greatest flexibility allowing you to react quickly to changes in market demand.